JP90-Z Render sprayer with mixer pump

"Wall goe" development and technology team, improve the JP90Z light steel wall spraying machine recenly. Made a technical upgrade to make the machine more prominent advantages, overall performance, which is well used in the domestic assembly-type construction industry, and played an unparalleled role, which is highly appreciated by users, as the pride of similar products.

Technical parameters of JP90-Z automatic spraying machine

Model | JP90-Z | Maximum particle size | 6mm |

Power supply | 380V 50HZ | Displacement | 115L/min 9m3/h |

Motor Power | 6.5kw/8kw | Delivery pressure | 30bar |

Air Compressor power | with external air compressor | Horizontal delivery distance | 60m |

Mixing motor power | 3kw | Vertical conveying distance | 30m |

mixing cylinder capacity | 200/260L | | |

water Pump motor | 0.75kw | Weight | 420kg |

Mixing cylinder capacity | 160L | Size (L × W × H) | 2200mm×700mm×1150mm |

Note: The above figures are only for reference, due to differences in physical and chemical properties of selected mortar, its each value is different accordingly.

***Highlights 1***

The use of cam structure mixer open the door technology (Patent No. ZL2017.Z131397.0)

Advantages: high sealing, easy opening and closing, self-cleaning edge mortar.

***Highlights 2***

large diameter mixer outlet

Advantages: to achieve an instant memory capacity of 260 liters of mixed mortar displacement

***Highlight 3***:

Application of mini remote sensing controller

Advantages: long-range sensitivity, suitable for messy long-distance control of mechanical work at any time.

***Highlights 4***

a slurry leak-proof seal applications (Patent No. ZL2012.2.0227665.2)

Advantages: Establish an firewall which will protect the pump motor when the motor back to hopper

***Highlights 5***

design double helical compulsory mixer blade

Advantages: The mixed slurry can produce a strong radial flow and axial flow, the contact surface between the mixed components, good encapsulation, and high-speed mixing slurry.

***Highlights 6***

set the screw pump decomposition mechanism

Advantages: no tools at the construction site, the rotor can be directly seperatedly from the stator on machine.

***Highlights 7***

configuration solid rubber wheels

Advantages: eliminate the troubles caused by the tire puncture in the construction site,

***Highlights 8***

accurate and simple water supply measurement unit

Advantages: Intuitive and easy to adjust water demand.

***Highlights 9***

set stirring body multi-directional screw pressure spray watering device

Advantages: From the peripheral edge of the stirring body at different angles to the stirring blade firing spiral pressurized water, stirring the body is not sticky slurry, energy saving materials, easy to clean.

***Highlights ten***

Set the cylinder action visible cover

Advantages: The opening and closing the feeding door by the cylinder to complete, intuitive mixing slurry mixing process.

***Highlights Eleven***

Set up a safety net mesh packer

Advantages: Operators in the state of rapid mechanical operation can be guaranteed.

***Highlights 12***

Configuration 100L of specific mixing motor

Advantages: Enough torque for better mixing of highly viscous stock.

***Highlights 13***

set double-headed cross-shaft coupling axis

Advantages: Significantly enhance the degree of freedom spray machine screw pump.

***Highlights 14***

mixing body center design

Advantages: Sprayer built-in structure of the working state is intuitive, easy to maintain.

***Highlights fifteen***

advanced electronic control procedures

Advantages: to achieve the firstly connect, secondly release,firstly off, secondly anti-pump program electronic control methods to improve mechanical efficiency.

Company Information

***10000 Square Meters factory plant,with more than 100 works

We have study and produce concrete machine Since 1973.

***Excellent Showroom

Most machine are in warehose if the phase is 3 phase, 380V,50HZ.

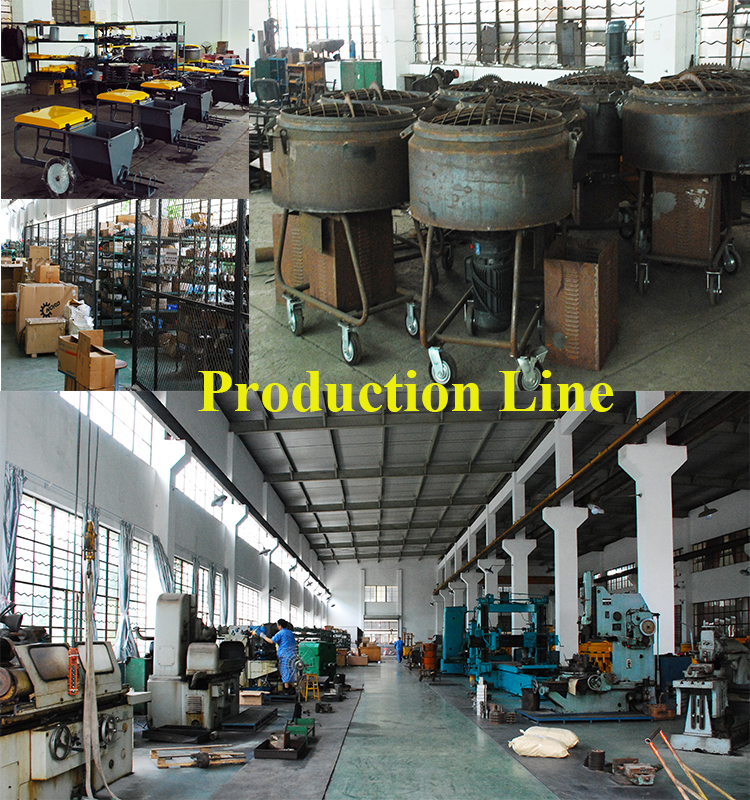

***Professional Production Line

Most of our workers are working here over 10-20 years

Certifications

***CE certification

***ISO 9001 certification

***NGV certification

Patent & Pride from Wallgoe:

Packaging & Shipping

***Wooden case packing

Full container shipment---wooden pallent package

LCL shipment----wooden carton package

FAQ

1. Q: Which pump model or plastering machine should we choose?

A: To recommend the most suitable model, please tell us:

- Material: composition, max aggregate size

-use for plastering or grouting?

- Capacity (-m3/h) :

- Delivery distance (horizontally / vertically):

- Grouting pressure:

- Driven type: electric motor, diesel engine, pneumatic motor

2. Q: What is the vulnerable part? How many spares should we prepare?

A:Screw type plastering machine

Rotor and stator would be worn out after 1-4 weeks depends on material and operation period.suggest purchase 4--6 sets.

Concrete pump:

After long-time running, the rubber piston and cylinder sleeve may get worn. We will offer some spares for free.

Referring to the service life of each part, we will put a rough estimate of requested spares according to your project scale.

3. Q: Can we have customized model?

A: Yes. Customized production and OEM production are available according to your actual requirements.

4. Q: Do i need technical skills to operate this machine?

A: Yes. Please read the Operation Instruction for some basic technical skills before operating this machine, and contact us if any operation procedure is unclear.

5. Q: What should we do if there are some problems with the machine?

A: The Operate Instruction will help with routine maintenance and common problems.

Also, you can contact us for technical instruction by email, instant messenger or live video etc.

6. Q: What is the lead time?

A: 1 week if voltage is 3 phase 380v 50hz. 20-40 days if other voltage.

7. Q: How about the package?

A: The machine will be wrapped by plastic film and packed by fumigation-free wooden case along with spare parts.

8. Q: How to place an order?

A: Both online order and offline order are acceptable.

It is suggested to place online order with a Trade Assurance to get full protection for first order.

9. Q :How to pay for this order?

A: Generally, TT, 30% deposit 70% before shipment;

L/C at sight (high bank charge, not suggest, but acceptable);

100% TT in advance (especially for small amount and spare parts etc.)

Contact

Tel: +86 577-86529608

Fax: +86 577-86529637

Mobile: +86 (Whatsapp/Wechat)

Skype: kellyzheng55

QQ: 330363227

Email: sales @cngcjx.com